Introduction

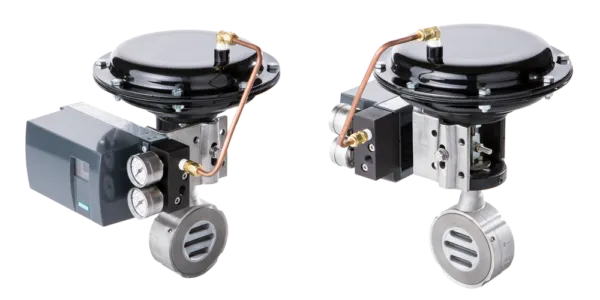

Wafer type control valves are integral components in fluid control systems across various industries. Their unique design offers several advantages over more traditional valve types, including a wafer-style body that brings benefits in terms of pricing, weight, and ease of installation. In this article, we'll take an in-depth look at the wafer type control valve, its key features, advantages, and the reasons it has become a popular choice for industries that require precise control over flow rates.

Pricing Advantage: Affordable and Cost-Effective

One of the most significant benefits of the wafer type control valve is its pricing advantage. Compared to other valve designs, wafer valves feature a streamlined body that minimizes material costs, allowing manufacturers to offer them at a lower price. This advantage makes the wafer type control valve an attractive option for industries that need to manage costs while still achieving reliable and efficient fluid control.

The wafer-style body is compact and designed to fit between flanges, which reduces the need for additional materials, contributing to its overall cost-effectiveness. Companies that require large numbers of valves can see considerable savings without compromising on performance or quality.

Weight Advantage: Lower Weight for Easier Installation

The wafer type control valve is also highly advantageous in terms of weight. Its compact design means that it weighs significantly less than other valve types. This reduction in weight not only saves on material costs but also decreases the time and expense associated with installation and ongoing maintenance.

Due to its lighter weight, wafer valves are easier to handle during the installation process, requiring fewer support structures. This results in shorter installation times, lower labor costs, and reduced downtime. In environments where space and weight are concerns—such as on offshore platforms, chemical plants, or industrial facilities—wafer type control valves offer a distinct advantage.

Capacity: Exceptional Flow in a Compact Body

Despite its compact size, the wafer type control valve boasts impressive capacity. These valves are designed to handle significant flow rates while maintaining precise control. The wafer-style body ensures a high flow coefficient (Cv), allowing fluid to pass through with minimal resistance.

For systems that demand tight control of flow rates, the wafer type control valve is an ideal solution. Its high capacity in such a compact form factor makes it suitable for a wide range of applications, including chemical processing, HVAC systems, water treatment, and more. These valves offer performance that rivals larger, bulkier options without taking up as much space.

Ease of Maintenance: Quick and Simple Servicing

Maintenance is a key consideration for any valve system, and wafer type control valves shine in this regard. The innovative "T-slot" design of the disc connection allows for rapid disassembly and reassembly, making it easy to reverse functions and perform necessary repairs or adjustments.

This feature significantly reduces maintenance downtime, ensuring that systems remain operational with minimal disruption. Quick access to internal components means that routine maintenance can be carried out efficiently, leading to lower operational costs over the long term.

Sizes and Body Materials: Versatile Options for Diverse Applications

Wafer type control valves are available in a range of sizes and materials, allowing them to be tailored to various applications. Standard sizes range from 1 inch to 8 inches (DN25 to DN200), covering a broad spectrum of flow requirements. This versatility makes them a popular choice in industries such as petrochemical, pharmaceutical, food and beverage, and more.

The body materials for these valves include stainless steel and carbon steel, both of which offer durability and resistance to corrosion. Stainless steel is often chosen for applications where high resistance to corrosion is necessary, while carbon steel provides strength and reliability in demanding industrial environments. The selection of materials ensures that wafer type control valves can handle a wide array of media, from aggressive chemicals to clean water.

Flow Coefficient (Cv) and Range

The wafer type control valve offers a high flow coefficient (Cv) of up to 600 (with a corresponding Kv of up to 519). This allows for efficient fluid transfer through the valve with minimal pressure loss. The Cv rating is a critical factor in determining how much flow a valve can handle, and the wafer type valve’s high capacity makes it ideal for systems requiring both precision and high throughput.

In terms of pressure ranges, the wafer type control valve accommodates ranges of 3-15 psi, 3-9 psi*, 9-15 psi*, and 6-30 psi (0.2-1.0 bar; 0.2-0.6 bar*; 0.6-1.0 bar*; and 0.4-2.1 bar), with some ranges requiring a positioner for optimal performance. This flexibility makes these valves suitable for a variety of applications that require different pressure controls.

Turndown Ratio: Precision Control with a 100:1 Ratio

A key performance feature of the wafer type control valve is its turndown ratio, which is an impressive 100:1. The turndown ratio is the measure of how precisely the valve can control flow rates, and a higher ratio indicates better accuracy and control.

This means the wafer type control valve can accurately manage flow from very low rates to high flow capacities, providing exceptional control across a wide range of operating conditions. For applications requiring fine-tuned flow control—such as in chemical dosing or process control—the wafer type valve's high turndown ratio is invaluable.

Shutoff Capability: ANSI Class IV Tightness

When it comes to shutoff capabilities, the wafer type control valve is rated for ANSI Class IV tightness. This classification ensures that the valve provides a high level of sealing, reducing leakage when the valve is closed. ANSI Class IV allows for very tight shutoff, which is especially important in systems where leakage could cause safety concerns, product contamination, or operational inefficiencies.

The tight shutoff feature makes wafer type control valves suitable for applications that require both precise flow control and the ability to completely stop flow when necessary.

Conclusion

The wafer type control valve offers a range of benefits that make it a highly desirable option for many industrial applications. With advantages in pricing, weight, capacity, and ease of maintenance, these valves provide reliable performance while reducing costs and installation times. Available in a variety of sizes and materials, wafer type control valves are versatile enough to be used in numerous industries, from chemical processing to HVAC systems.

With a high Cv rating, a broad range of pressure capabilities, a 100:1 turndown ratio, and ANSI Class IV shutoff, wafer type control valves are engineered for precision and durability. Their compact design and innovative features make them a top choice for efficient, cost-effective flow control.