- Hits: 1

- Categories: Butterfly Control Valves

- Tags: Soft Seal Butterfly Control Valve , ASTM A216 WCB Butterfly Control Valve , 8 Inch Butterfly Control Valve

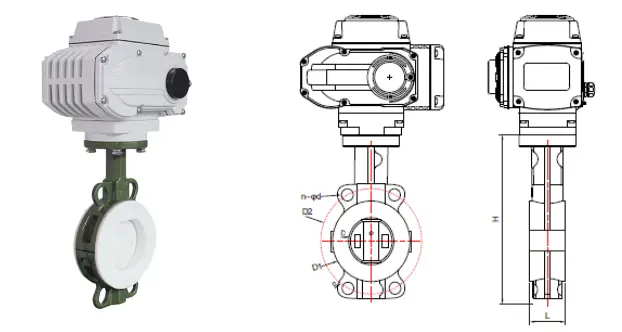

Butterfly Control Valve Body Advantages

Construct: Simpler, lighter, and more compact structure.

Medium: Convey muck and gather the least amount of liquid at the pipeline's mouth

Maintenance: A 2-section valve stem is pinless. Maintenance and disassembly are easy.

Sealing: PTFE, The sealing substance is corrosion and age resistant

Actuator: On-off type, adjustable type, intelligent type can be optional

Fast and Responsive: Quick opening and closing function.

Low and High-temperature Resistance: PDEM: -10℃ ~120℃ / PTFE: -30℃ ~180℃

Butterfly Control Valve Body Features

Butterfly valve: Wafer, Flanged Type, Lug

Material: Cast Iron, Carbon Steel(WCB), Stainless Steel(CF8, CF8M)

Standard: GB/ANSI/JIS/DIN

Special Requirements: High pressure, high temperature, strong corrosion can be customized

Stem Seal: Not easily deformed, avoiding the usual stem leakage

Automated Centering Function: Achieve the minimal interference fit between the butterfly plate and the valve seat