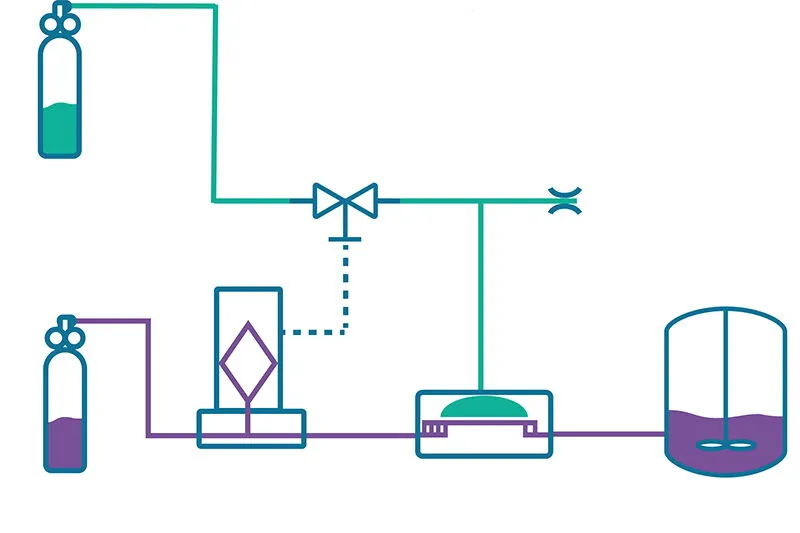

Flow control valves regulate fluid or gas flow in a system, while pressure control valves adjust fluid pressure within pipes. Pneumatic systems are widely used due to their cost-effectiveness in delivering power and energy to tools, instrumentation, and industrial processes. These systems rely on both pressure and flow to function effectively. While pressure control and flow control are distinct, they are interconnected, and adjusting one affects the other. Here’s a breakdown of their definitions, relationship, and common devices used in pneumatic applications.

Pressure and Flow in Pneumatic Systems

Pressure in pneumatic systems is the force exerted across a given area. It determines the strength of the compressed air, crucial for powering applications. Flow, on the other hand, refers to the volume and speed at which pressurized air moves through the system over time. It governs how quickly the air reaches its destination.

Both pressure and flow are essential for pneumatic systems to operate efficiently. Without adequate pressure, the air lacks the force needed for applications. Without proper flow, the air remains confined and cannot perform work.

Pressure Control vs. Flow Control

Pressure Control: Focuses on regulating the force of the air within the system. It ensures that the pressure remains constant at the required level for consistent operation. Devices like pressure regulators are used to achieve this.

Flow Control: Governs the speed and volume of air movement. By adjusting the opening or closing of flow control valves, it manages how much and how fast the air flows through the system, maintaining efficiency and preventing overconsumption of air.

These controls are interdependent; changes in one affect the other. For instance, attempting to control flow using pressure can lead to inefficiencies and increased energy costs due to excess airflow. Conversely, using flow control to manage pressure may result in pressure drops or unstable supply when airflow is increased or decreased.

Pressure and Flow Control Devices

Flow Control Valves:

Proportional Control Valves: Adjust airflow proportionally to varying electrical signals.

Ball Valves: Enable or block airflow by rotating a ball inside the valve.

Butterfly Valves: Use a metal plate to regulate airflow.

Needle Valves: Control airflow precisely using a needle mechanism.

Pressure Control Devices:

Pressure Relief Valves: Prevent excess pressure buildup by releasing air when pressure exceeds safe limits.

Pressure Reducing Valves: Maintain lower pressures in systems to prevent over-pressurization.

Sequencing Valves: Regulate actuator movement sequence in systems with multiple actuators.

Counterbalance Valves: Stabilize pressure in parts of the system to counter external forces effectively.

Conclusion:

Effective pneumatic system operation hinges on well-managed pressure and flow. While these controls are interconnected, managing them separately with appropriate devices ensures efficiency and prevents system damage or energy wastage. Understanding these principles and employing suitable control devices are crucial for optimizing pneumatic system performance in various industrial applications.

Pressure and Flow in Pneumatic Systems

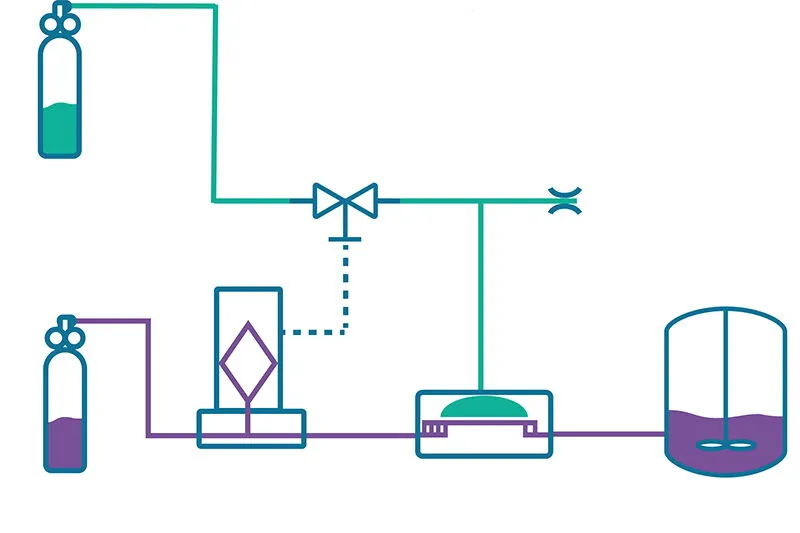

Pressure in pneumatic systems is the force exerted across a given area. It determines the strength of the compressed air, crucial for powering applications. Flow, on the other hand, refers to the volume and speed at which pressurized air moves through the system over time. It governs how quickly the air reaches its destination.

Both pressure and flow are essential for pneumatic systems to operate efficiently. Without adequate pressure, the air lacks the force needed for applications. Without proper flow, the air remains confined and cannot perform work.

Pressure Control vs. Flow Control

Pressure Control: Focuses on regulating the force of the air within the system. It ensures that the pressure remains constant at the required level for consistent operation. Devices like pressure regulators are used to achieve this.

Flow Control: Governs the speed and volume of air movement. By adjusting the opening or closing of flow control valves, it manages how much and how fast the air flows through the system, maintaining efficiency and preventing overconsumption of air.

These controls are interdependent; changes in one affect the other. For instance, attempting to control flow using pressure can lead to inefficiencies and increased energy costs due to excess airflow. Conversely, using flow control to manage pressure may result in pressure drops or unstable supply when airflow is increased or decreased.

Pressure and Flow Control Devices

Flow Control Valves:

Proportional Control Valves: Adjust airflow proportionally to varying electrical signals.

Ball Valves: Enable or block airflow by rotating a ball inside the valve.

Butterfly Valves: Use a metal plate to regulate airflow.

Needle Valves: Control airflow precisely using a needle mechanism.

Pressure Control Devices:

Pressure Relief Valves: Prevent excess pressure buildup by releasing air when pressure exceeds safe limits.

Pressure Reducing Valves: Maintain lower pressures in systems to prevent over-pressurization.

Sequencing Valves: Regulate actuator movement sequence in systems with multiple actuators.

Counterbalance Valves: Stabilize pressure in parts of the system to counter external forces effectively.

Conclusion:

Effective pneumatic system operation hinges on well-managed pressure and flow. While these controls are interconnected, managing them separately with appropriate devices ensures efficiency and prevents system damage or energy wastage. Understanding these principles and employing suitable control devices are crucial for optimizing pneumatic system performance in various industrial applications.