Control valves are essential components found in various industries, playing crucial roles in managing fluid flow within systems to uphold specific parameters such as flow rate, pressure, temperature, or level. They come in manual or automatic variants, and their correct selection and maintenance are vital for optimizing process efficiency, minimizing downtime, and improving overall productivity.

Each valve is designed with unique specifications, tailored for specific purposes, making careful consideration necessary before procurement or implementation. With numerous options available, users may require guidance in choosing the most suitable valve for their requirements. Factors such as application, flow rate, pressure, temperature, and material compatibility must be thoroughly evaluated to ensure the selected valve meets the specific needs. Seeking advice from valve experts or referring to technical specifications can aid users in making informed decisions.

In the wastewater treatment industry, control valves play a critical role in regulating fluid flow and temperature to support the efficient operation of systems and ensure environmental protection. However, managing wastewater involves dealing with a wide range of temperatures, from low temperatures in sewage storage areas to high temperatures in treatment processes. This necessitates the use of different types of control valves to effectively address temperature-related challenges. This article provides a comprehensive guide to assist in selecting suitable control valves tailored to the diverse temperature conditions encountered in wastewater treatment.

Factors to Consider When Selecting a Process Control Valve

Flow Control Characteristics:

It's crucial to understand the maximum and minimum pressures and the acceptable temperature for fluid transfer. Knowledge of the valve's inlet and outlet pressures helps choose a valve with the right specifications. Also, consider fluid viscosity and flow rate to ensure the valve can handle the volume and consistency of the fluid. These factors greatly affect the valve's performance and efficiency.

Fluid Nature:

Valve specifications depend on the type of fluid being transferred. Control valves manage various substances like natural gas, steam, water flow, etc. It's vital that the valve is compatible with the specific fluid it will handle.

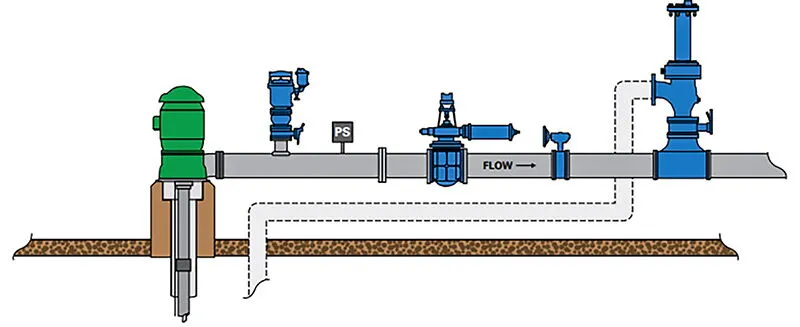

Compatibility with Remote Systems:

In some processes, control may need to be done remotely due to hazardous environments. Choose a valve type compatible with remote process management systems. This ensures easy remote control and supervision, enhancing operational safety and efficiency.

Temperature Considerations:

The temperature of the system media and the ambient operating temperature of the process environment are critical factors. These temperatures may fluctuate during the process or remain constant. It's essential for the valve to accommodate such temperature variations to prevent issues like expansion and contraction that could impede fluid flow. At high temperatures, metallic components may experience rapid strength loss. Hence, selecting a valve made from appropriate materials meeting temperature specifications is vital. Such considerations can impact pressure ratings, potentially reducing them over time.

Selecting the appropriate valve for varying temperature ranges requires careful consideration of several factors, including the valve's material composition, the temperature of the flowing media, and the ambient process temperature. It's crucial to ensure that the valve's temperature range and pressure rating align with the application to mitigate any potential damage or failure.

For processes operating at low temperatures, it's vital to avoid materials lacking low-temperature resistance. Instead, opt for specialized valves featuring ceramic lining and a cooling jacket structure. The cooling jacket's water circulation system helps maintain the internal metal of the valve within acceptable stress limits.

In environments with temperatures below -29°C, valves made of low-temperature resistant materials are recommended. These materials possess excellent heat capacity and high toughness, minimizing the risk of valve cracking due to cooling loads.

For applications like sewage storage areas or cold-climate wastewater treatment facilities, selecting appropriate control valves is crucial. Material selection becomes particularly critical to ensure valve reliability and performance in extreme temperatures. Common low-temperature materials include stainless steel, carbon steel, and specialized low-temperature alloys, known for their excellent low-temperature characteristics and corrosion resistance. Moreover, control valve designs for low-temperature environments should address the selection of sealing materials and valve insulation measures to prevent frost and freezing.

In ambient temperature settings, such as most wastewater treatment facilities, where temperatures typically range from 0°C to 40°C, selecting control valves is relatively straightforward. Many common materials can adapt to this temperature range, including stainless steel, copper alloys, PVC, and polypropylene, all offering good corrosion resistance and temperature tolerance, meeting the demands of most ambient temperature environments.

Certain wastewater treatment processes may involve handling high-temperature wastewater or undergoing high-temperature treatment procedures, necessitating the use of valves suitable for such environments. In high-temperature settings, conventional metal materials may soften, oxidize, or deform, thus requiring materials with exceptional high-temperature stability, such as nickel-based alloys, titanium alloys, and chromium-molybdenum alloys. Additionally, control valve designs for high-temperature environments should address valve sealing performance and incorporate lubrication systems to ensure normal operation and safety.