- Hits: 2

- Categories: Ball Control Valves

- Tags: Explosion-proof Ball Control Valve , SS 304 Ball Control Valve , Stainless Steel Ball Control Valve

Product Name: Explosion-proof Ball Control Valve

Material: Stainless Steel, SS 304, SS 316

Seat Material: EPDM/PTFE

Nominal Size: 2 Inch, DN50

Pressure Rating: Class 150 LB, PN20

Connection Type: Flanged

Working Temperature: EPDM: -45℃ - 80℃ / PTFE: -30℃ - 180℃

Structure Type: Floating ball core, 3way-T type, 3way-L type

Applications: Food & Beverage, Water & Wastewater, Ultra Pure Water, Desalination, Chemical, Textile, Pharmaceutical, Pulp & Paper, Mining, Boiler and Power Industries

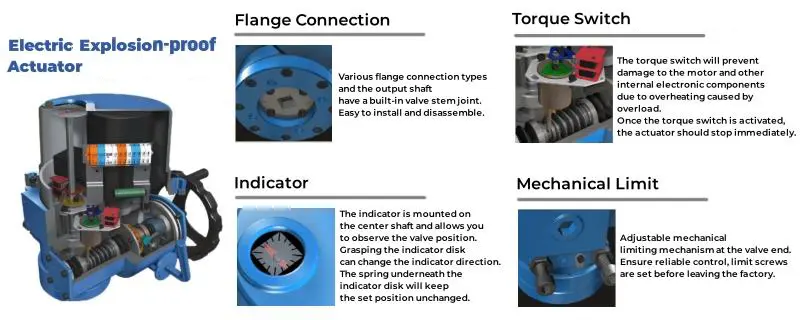

Explosion-Proof Actuator Features:

Housing: Constructed from durable aluminum alloy, undergoes anodic oxidation and polyester powder coating for superior corrosion resistance. Offers IP67, NEMA4 and 6 protection, with optional IP68 and explosion-proof types.

Motor: Fully enclosed squirrel-cage motor, compact yet powerful with low inertia force. Insulation class F, equipped with built-in thermal protection to prevent overheating.

Indicator: Mounted on central shaft for easy valve position observation. Convex lens design prevents water accumulation, ensuring clear visibility.

Limit Switch: Mechanical + electronic limit. Adjustable mechanical limit screw ensures safety and reliability. Electronic limit switch operated by cam mechanism allows precise positioning adjustment without battery support (all micro-switch contacts are silver).

Stainless Steel Ball Valve Features:

Easy Installation: Designed for self-disassembly and installation.

Anti-Corrosion: Ideal for use in corrosive environments and extreme temperatures.

Full Port: Minimizes risk of blockages or clogging.

Low Fluid Resistance: Offers minimal resistance comparable to a same-length pipe segment.

Standard: Complies with GB/ANSI/JIS/DIN standards.

Special Requirements: Customizable for high pressure, high temperature, and strong corrosion environments.